Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Parker Braven is at the forefront of a new wave of quality-engineered solution providers in a world where the demand for customization and precision continues to grow.

Sustainable engineering and manufacturing take on new meaning with Parker Braven‘s world-class “one-stop-shop” infrastructure, where the entire manufacturing process occurs under one roof. This demonstrates Parker Braven‘s collaborative culture based on reliability, quality, and workplace safety.

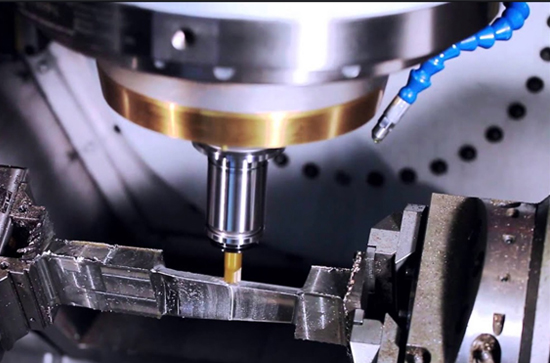

Parker Braven offers precision CNC machining under contract and is committed in providing exceptional value through competitive pricing, superior quality, reliable and on-time delivery, and outstanding customer service.

Using CNC technology, we have positioned ourselves to offer you the most competitive price and delivery for your precision machined components and assemblies.

Leadership

Focused teams are driving progress.

Continuous Improvement

Continually track performance measures to improve employees, products, and systems.

Equal Opportunity

All people, employees, and service providers are treated without discrimination, primarily based on gender, race, or age.

Be Innovative

Adapt and implement value-added technology in manufacturing processes.

Parker Braven provides all the manufacturing solutions such as advanced machining of precision components, sub-assemblies & assemblies under one roof. The engineering capability of our company, evolved over a decade, has enabled us to consistently offer quality complex precision manufactured components and assemblies, within stipulated timelines and at reasonable cost, allowing us to forge a robust relationship with our customers.

1.Precision machining upto cnc 5 axis milling & turning

2.Cad cam and reverse engineering

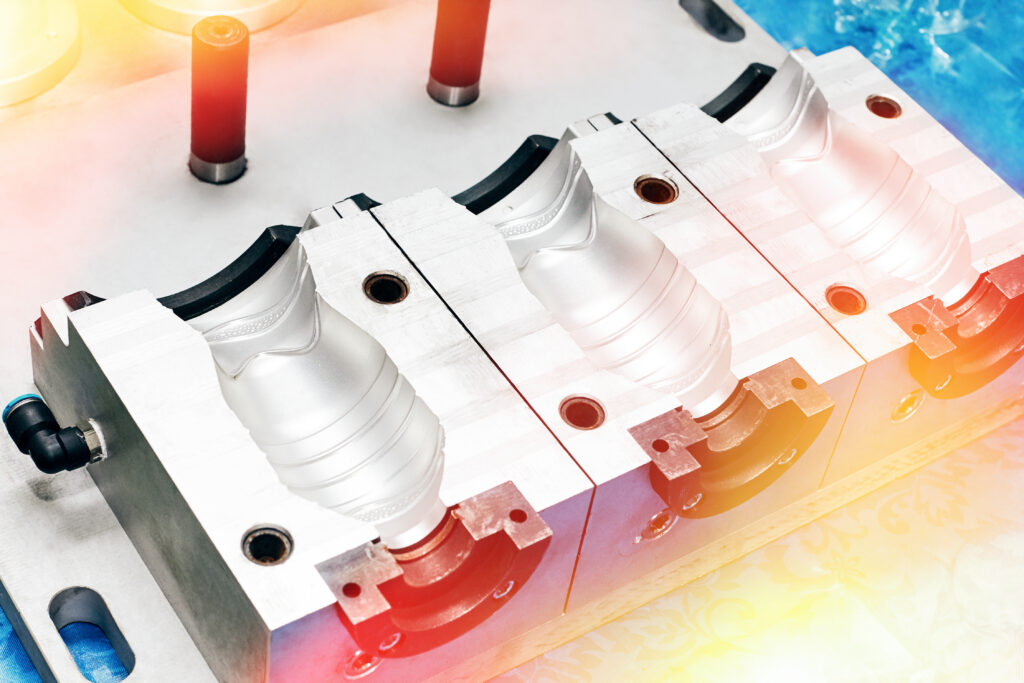

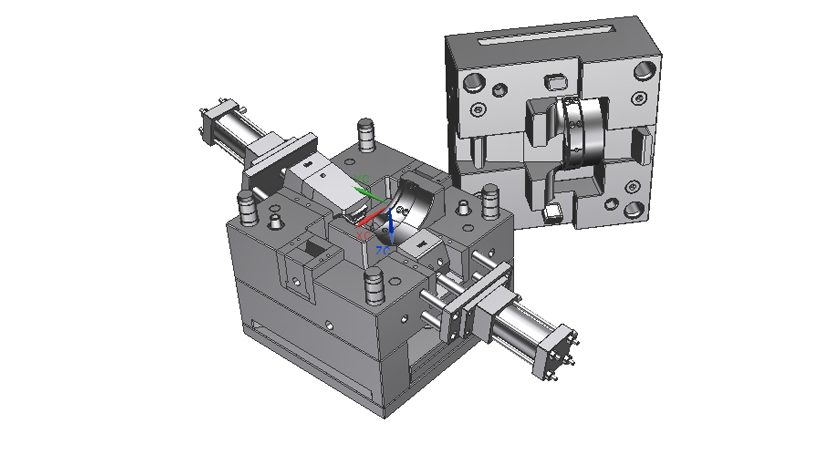

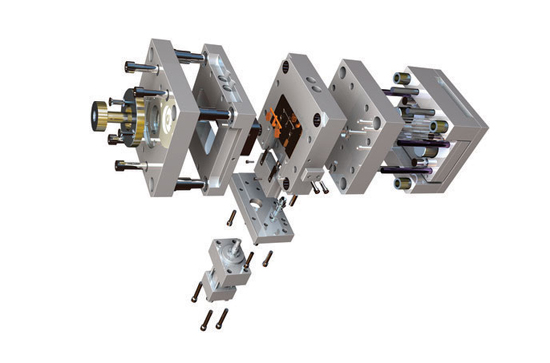

3.Tool room which can manufacture complex injection moulds, die casting dies, rubber moulds and complex fixtures.

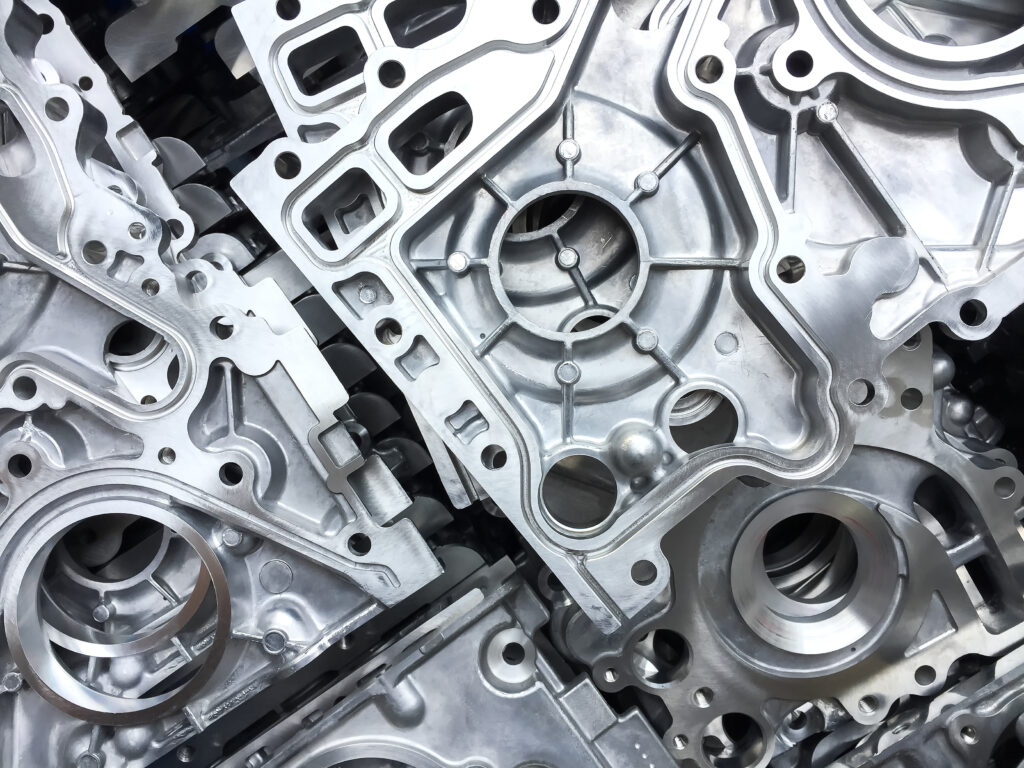

OIL & GAS

AEROSPACE

DEFENCE

AERONAUTICAL

INJECTION MOULDS

CASTED COMPONENTS

Parker Braven provides all the manufacturing solutions such as advanced machining of precision components, sub-assemblies & assemblies under one roof. The engineering capability of our company, evolved over a decade, has enabled us to consistently offer quality complex precision manufactured components and assemblies, within stipulated timelines and at reasonable cost, allowing us to forge a robust relationship with our customers.

1.Inhouse 5 axis cnc milling, cnc turning & cnc edm with an accuracy up to 10 microns..

2.Expertise in handling rm such as inconel, hastelloy, nimonic, titanium, steel, aluminium, bronze etc

3.Can handle raw material to machining, forging to machining & casting to machining.

4.Stringent quality control with cmm to ensure the quality of component produced

5.Capable of handling all kinds of surface coatings on the components..

6.Currently offering services to defense, aerospace, oil & gas & architectural industries.

Parker Braven have well experienced tool designers, cnc programmers equipped with state of art cad cam softwares capable of handling all type of 2d & 3d drawing conversions, 3 axis, 4 axis and 5 axis cnc programming.

1.2d drawings to 3d models for manufacturing using high end cad softwares

2.Conversion of other standards to iso standards for easy processing(inches to mm, russian ghost to iso)

3.Conversion of point cloud data, co-ordinates data or complex profiles from equations/ expressions to 3d models

4.Detailed process plan and drafting of detailed 2d drawings for various operations like drilling, boring, turning and spark erosion.

5.Reverse engineering from sample component by cmm, 3d scanning and 3d printed samples for testing before production.

6.Cnc programming for 2d operations, 3axis, 4 axis and 5 axis 3d programs using high end cam softwares

7.Design and development of jigs and fixtures for high productivity with repeatability, quality and assures fool proofing

We have tool room facility equipped with highly skilled tool designers,die makers & machine operators with state of art machining facility ,capable of manufacturing highly complicated plastic injection moulds, die casting dies and rubber moulds, based on qty and customer requirement

1.Manufacturing injection molds, die casting dies, rubber molds

2.Manufacturing machined fixture, welded fixture for aerospace, defense, oil & gas & construction sectors

3.Production of injection molded components, pressure die casted components

4.Moulding/casting semifinished component and undergoes finish machining

5.Finished components by moulding and casting operations if the volume is high

We Parker Braven family is committed to supply productive, high quality and reliable products through the effective application of QMS and continual improvement of design and manufacturing process

New product development, Effective utilization of resources, Improved customer satisfaction, Improved supplier performance, Reduced pro-duct related complaints, Human resources development

The team of high qualified engineers and technicians and skilled workers inspired by the uniform desire to give their respective best in manufacturing everything at Parker Braven

Parker Braven has now established itself firmly as a manufacturer of high quality precision components & assemblies. Customers have benefitted in quality, time & cost, by Parker Braven‘s innovative design, alternative materials, advanced techniques and they are rewarding us with repeated orders. Parker Braven continues to make ongoing investments on equipment and up-gradation of technologies to keep up-to-date in the industry and to meet the emerging new challenges.